Aluminum curtain walls have revolutionized the architectural landscape, gracing modern buildings with sleek aesthetics and exceptional performance. These non-load-bearing exterior walls, typically composed of aluminum frames and infill panels, offer a myriad of benefits, including enhanced energy efficiency, natural lighting optimization, and architectural versatility.

Understanding the Anatomy of an Aluminum Curtain Wall

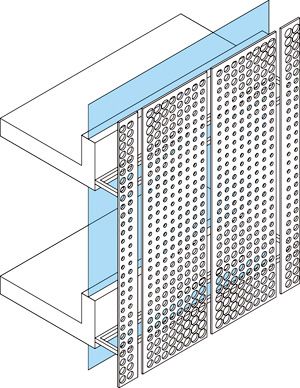

To fully grasp the intricacies of aluminum curtain walls, it’s essential to delve into their constituent components. While the specific composition may vary depending on the manufacturer and design requirements, the core components of an aluminum curtain wall system typically encompass:

- Mullions: The vertical backbone of the curtain wall system, mullions are extruded aluminum members that provide structural support and define the overall grid of the façade. They are responsible for transferring wind and gravity loads to the building structure.

- Transoms: Horizontal members that connect mullions at predetermined intervals, transoms contribute to the structural integrity of the curtain wall system and provide attachment points for infill panels.

- Infill Panels: The non-structural components that fill the spaces between mullions and transoms, infill panels can be composed of various materials, including glass, metal panels, or stone. They serve as the primary visual element of the curtain wall and contribute to the overall thermal performance and aesthetic appeal of the building.

- Gaskets and Sealants: To ensure watertightness and air infiltration resistance, gaskets and sealants are employed at the joints between mullions, transoms, and infill panels. These components play a crucial role in preventing moisture intrusion and maintaining the building’s envelope integrity.

- Anchors and Brackets: The connection points between the curtain wall system and the primary building structure are established through anchors and brackets. These components ensure the secure attachment of the curtain wall and transfer loads effectively.

- Insulation: To enhance the thermal performance of the curtain wall system, insulation materials are often incorporated within the mullions, transoms, and around infill panels. This helps regulate the interior temperature of the building and reduces energy consumption.

- Accessories: A range of additional components, such as pressure plates, rain screens, and weep holes, may be integrated into the curtain wall system to address specific design requirements and enhance its performance.

The Intricacy of Curtain Wall Systems

The number of components in an aluminum curtain wall system can vary significantly depending on the project’s complexity, design specifications, and performance requirements. A simple stick-built curtain wall system may involve a relatively limited number of components, while a complex unitized curtain wall system with intricate details and specialized features could encompass a more extensive array of elements.

Conclusion

Aluminum curtain walls, with their intricate composition of various components, offer a versatile and high-performance solution for modern architecture. Understanding the individual components and their roles is essential for making informed decisions about curtain wall design, installation, and maintenance. By carefully selecting and integrating these components, architects and engineers can create stunning and sustainable façade solutions that enhance the aesthetic appeal, energy efficiency, and overall functionality of buildings.