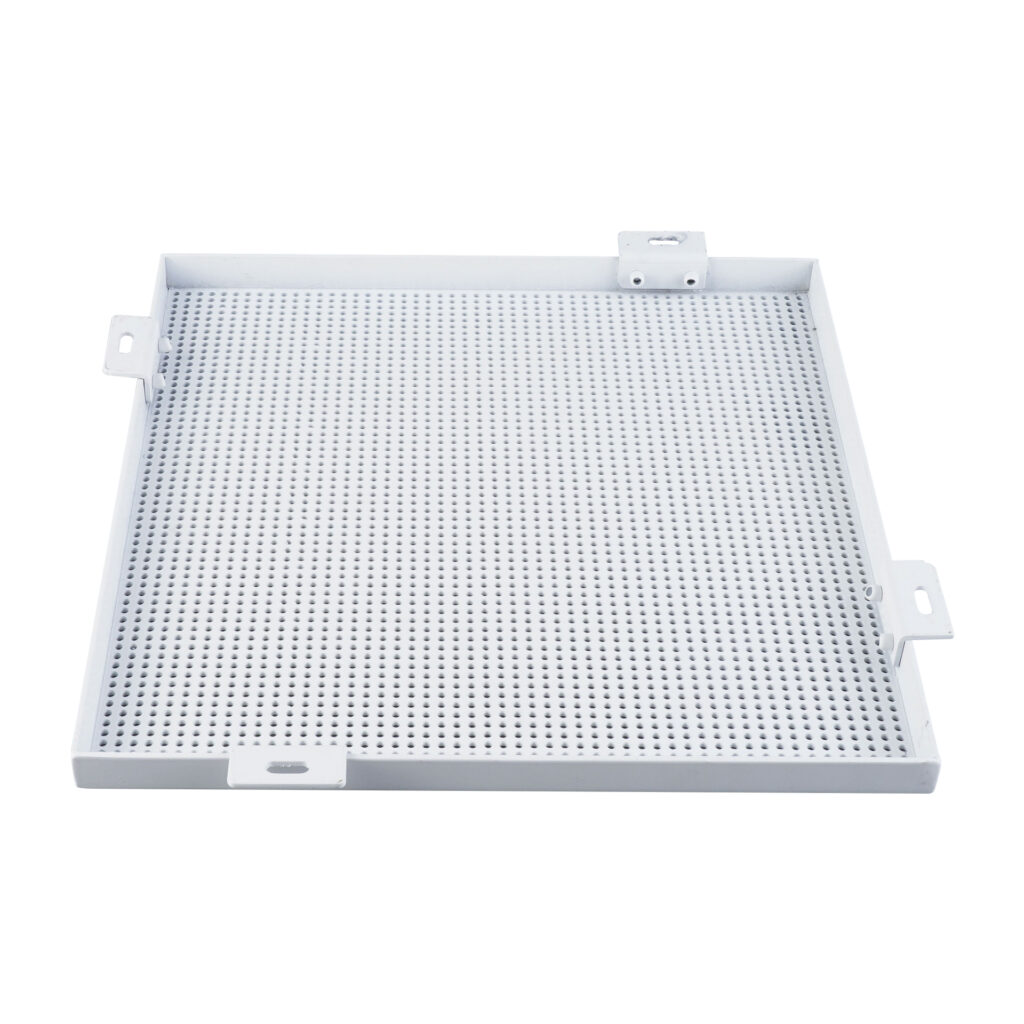

In modern architecture, Aluminum Facade Fire Resistance Rating have become a popular choice for their sleek appearance, durability, and versatility. However, one critical aspect that architects, engineers, and building contractors must consider is the aluminum facade fire resistance rating. This factor not only impacts the safety of a structure but also determines compliance with local building codes and regulations. This article delves into the importance of fire resistance ratings, testing standards, and best practices for ensuring safety when using aluminum facades.

What is an Aluminum Facade Fire Resistance Rating?

A fire resistance rating is a measure of how well a material or assembly can withstand fire and maintain its structural integrity for a specified period. This rating is expressed in minutes or hours (e.g., 30 minutes, 1 hour, 2 hours) and indicates the material’s ability to prevent fire spread, resist structural collapse, and insulate against heat.

For aluminum facades, fire resistance ratings are influenced by several factors, including the type of aluminum alloy, surface treatments, and the integration of fire-resistant components. Understanding these ratings is essential for ensuring compliance with safety standards and minimizing fire hazards.

For more detailed insights on aluminum facade systems, visit Likton Metal.

Fire Behavior of Aluminum

Aluminum is a non-combustible material, meaning it does not burn under normal conditions. However, its fire resistance depends on:

- Melting Point: Aluminum melts at approximately 660°C (1220°F), which is relatively low compared to other construction materials like steel. In intense fires, aluminum can lose its structural integrity.

- Heat Conduction: Aluminum’s high thermal conductivity can accelerate the spread of heat across its surface, potentially impacting adjacent materials.

To enhance fire resistance, aluminum facades are often paired with fire-rated insulation or protective coatings designed to withstand higher temperatures.

For an in-depth overview of fire-resistant materials, refer to National Fire Protection Association (NFPA).

Standards and Testing for Aluminum Facade Fire Resistance Ratings

The fire resistance of aluminum facades is evaluated through rigorous testing based on international standards, such as:

- EN 13501-1: This European standard classifies construction materials based on their reaction to fire, including flame spread, smoke production, and the presence of flaming droplets.

- ASTM E119: Widely used in the United States, this test evaluates the fire resistance of building materials and assemblies under controlled conditions.

- BS 8414: This British standard assesses the fire performance of external cladding systems, including aluminum facades.

Manufacturers typically provide certification for their aluminum facade systems, indicating compliance with these standards. When selecting materials, always verify their fire resistance ratings and ensure they meet local building codes.

Explore certified aluminum facade systems at Likton Metal.

Enhancing the Fire Resistance of Aluminum Facades

To maximize safety, consider the following strategies when working with aluminum facades:

- Fire-Rated Insulation: Use non-combustible insulation materials, such as mineral wool, to reduce the risk of fire spread behind the facade.

- Protective Coatings: Apply fire-retardant coatings to the aluminum surface to delay heat transfer and improve fire resistance.

- Composite Panels: Opt for aluminum composite panels (ACPs) with fire-resistant cores, such as those made of mineral-filled materials instead of polyethylene.

- Compartmentalization: Design the facade system with fire barriers and breaks to limit fire spread between sections.

For more information on fire-resistant building design, visit the International Code Council (ICC).

Regulatory Compliance and Best Practices

Adhering to building codes and fire safety regulations is non-negotiable when using aluminum facades. Some key considerations include:

- Local Regulations: Different regions have specific requirements for facade fire resistance. Familiarize yourself with local codes, such as the International Building Code (IBC) or European Union standards.

- Third-Party Testing: Choose materials and systems certified by accredited third-party organizations to ensure reliability.

- Regular Maintenance: Inspect facades periodically to identify potential fire hazards, such as damaged panels or compromised insulation.

For guidance on regulatory compliance, consult the experts at Likton Metal or explore resources from the European Committee for Standardization (CEN).

Conclusion

The aluminum facade fire resistance rating is a critical factor in modern building design, directly affecting safety and regulatory compliance. By understanding the behavior of aluminum under fire, adhering to testing standards, and implementing best practices, architects and contractors can create safe and aesthetically pleasing structures. When selecting aluminum facade systems, always prioritize certified materials and consult with fire safety experts to ensure optimal performance.

Learn more about high-quality aluminum facades at Likton Metal or explore additional guidelines from the International Fire Safety Standards Coalition (IFSS).