Aluminum Composite Material ACM panel systems are an innovative and versatile cladding solution widely used in modern architecture. This guide will provide an in-depth look at ACM panel systems, exploring their components, benefits, applications, and installation process. Whether you’re an architect, builder, or property owner, understanding ACM panel systems can help you make informed decisions for your next project.

Understanding ACM Panels

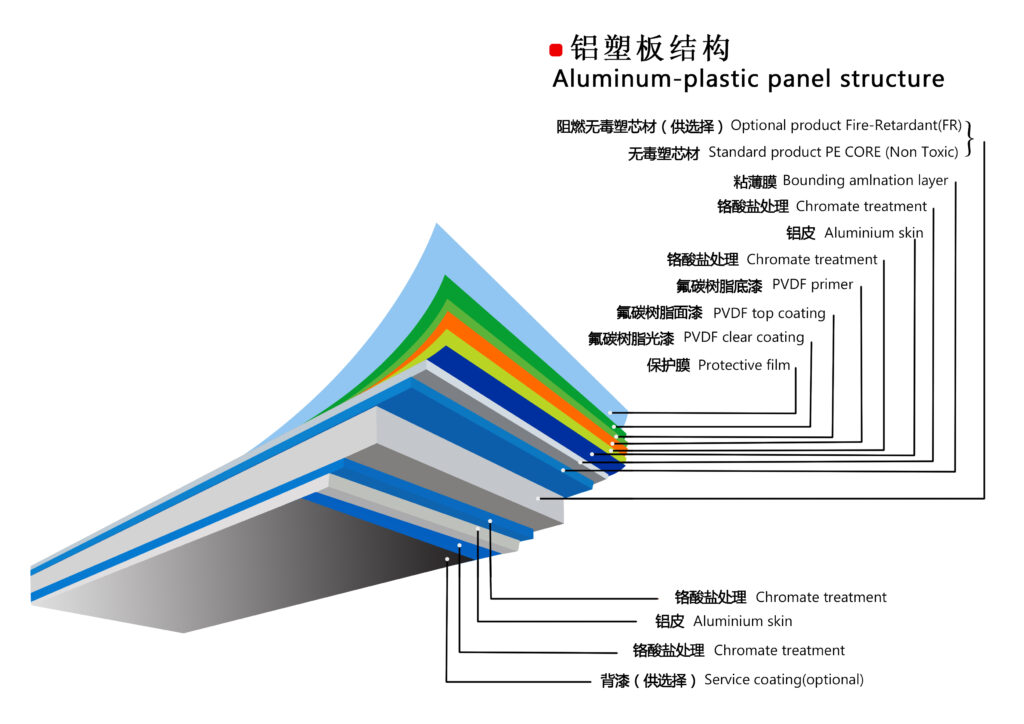

ACM panels consist of two thin layers of aluminum bonded to a non-aluminum core, usually made of polyethylene or a fire-resistant material. This combination creates a lightweight, durable, and aesthetically appealing panel suitable for various applications.

Components of ACM Panels

- Aluminum Sheets: The outer layers are made of aluminum, providing strength and rigidity.

- Core Material: The inner core can be polyethylene for standard applications or a mineral-filled core for enhanced fire resistance.

- Protective Coatings: These coatings protect the aluminum surface from corrosion, UV rays, and other environmental factors.

Benefits of ACM Panel Systems

ACM panel systems offer several advantages that make them a popular choice in construction and design.

Lightweight and Durable

ACM panels are lightweight yet strong, making them easy to handle and install. Their durability ensures long-lasting performance, even in harsh weather conditions.

Versatile Design Options

Available in a wide range of colors, finishes, and textures, ACM panels can be customized to fit various design aesthetics. They can mimic the appearance of other materials like wood or stone while providing the benefits of aluminum.

Cost-Effective

Compared to solid aluminum or other cladding materials, ACM panels are more cost-effective due to their lower material and installation costs.

Fire Resistance

With the option of fire-resistant cores, ACM panels can meet stringent fire safety standards, making them suitable for high-rise buildings and other structures where fire safety is a concern.

Low Maintenance

ACM panels require minimal maintenance. Their protective coatings resist dirt, stains, and graffiti, making them easy to clean and maintain over time.

Applications of ACM Panel Systems

ACM panel systems are used in a variety of applications, including:

Exterior Cladding

ACM panels are widely used for exterior cladding in commercial, residential, and industrial buildings. Their aesthetic appeal and durability make them an ideal choice for facades, canopies, and soffits.

Signage

The smooth surface and customizable design options of ACM panels make them perfect for signage. They are often used for storefront signs, billboards, and other advertising displays.

Interior Design

In addition to exterior applications, ACM panels are also used in interior design. They can create striking feature walls, partitions, and ceilings, adding a modern touch to any space.

Renovation Projects

ACM panels are ideal for renovation projects due to their lightweight and easy installation. They can quickly update the appearance of an old building, providing a fresh and modern look.

Installation Process of ACM Panel Systems

Installing ACM panel systems involves several steps to ensure a secure and professional finish.

Preparation

- Site Survey: Conduct a thorough site survey to assess the building structure and determine the installation requirements.

- Material Selection: Choose the appropriate ACM panels based on design specifications and performance requirements.

- Surface Preparation: Ensure the surface is clean, dry, and free of any debris or contaminants.

Fabrication

- Panel Cutting: Cut the ACM panels to the required sizes and shapes using specialized cutting tools.

- Edge Finishing: Apply edge finishing techniques to ensure smooth and safe edges.

- Drilling and Routing: Create holes and slots as needed for mounting and fastening the panels.

Installation

- Mounting System: Install the mounting system, which typically includes brackets, rails, and clips, to secure the panels to the building structure.

- Panel Attachment: Attach the ACM panels to the mounting system, ensuring they are level and properly aligned.

- Sealing and Caulking: Apply sealant and caulking to joints and seams to prevent water infiltration and ensure a weather-tight seal.

Finishing

- Inspection: Inspect the installation to ensure all panels are securely attached and aligned.

- Cleaning: Clean the panels to remove any installation debris and fingerprints.

- Final Touches: Apply any final touches, such as touch-up paint or protective coatings, to complete the installation.

Maintenance Tips for ACM Panel Systems

While ACM panels are low maintenance, regular care can extend their lifespan and maintain their appearance.

Cleaning

- Regular Cleaning: Clean the panels periodically with mild soap and water to remove dirt and grime.

- Stain Removal: Use non-abrasive cleaners for stubborn stains and avoid harsh chemicals that can damage the protective coatings.

Inspection

- Routine Inspections: Conduct routine inspections to check for any signs of damage, such as dents, scratches, or loose panels.

- Prompt Repairs: Address any issues promptly to prevent further damage and maintain the integrity of the cladding system.

Protective Measures

- Graffiti Protection: Apply anti-graffiti coatings in areas prone to vandalism to make cleaning easier.

- UV Protection: Ensure the protective coatings are maintained to prevent UV damage and color fading.

Conclusion

ACM panel systems offer a versatile, durable, and aesthetically pleasing solution for various architectural applications. From exterior cladding to interior design, ACM panels provide numerous benefits, including lightweight construction, design flexibility, and cost-effectiveness. By understanding the components, benefits, and installation process of ACM panel systems, you can make informed decisions for your next project and achieve a professional and long-lasting result.