In the ever-evolving landscape of architecture and construction, building facades serve as a crucial interface between the built environment and its surroundings. Among the myriad materials utilized in facade construction, aluminum panels have emerged as a prominent choice, driven by several key developmental trends.

1. Advancements in Material Science:

Aluminum, renowned for its exceptional strength-to-weight ratio and corrosion resistance, has long been favored in construction applications. Recent advancements in material science have further enhanced the properties of aluminum panels, resulting in increased durability, enhanced thermal performance, and improved sustainability. Innovations such as nano-coatings and alloy compositions have enabled aluminum panels to withstand harsh environmental conditions while maintaining their aesthetic appeal over extended periods.

2. Sustainable Practices and Green Building Initiatives:

The global shift towards sustainable practices and green building initiatives has significantly influenced the development of building facade materials. Aluminum panels, inherently recyclable and with a low environmental footprint, align seamlessly with these objectives. Manufacturers are increasingly sourcing recycled aluminum and employing energy-efficient production processes to minimize environmental impact. Additionally, aluminum panels contribute to energy efficiency in buildings by facilitating the integration of insulation materials and efficient HVAC systems.

3. Technological Integration and Digital Fabrication:

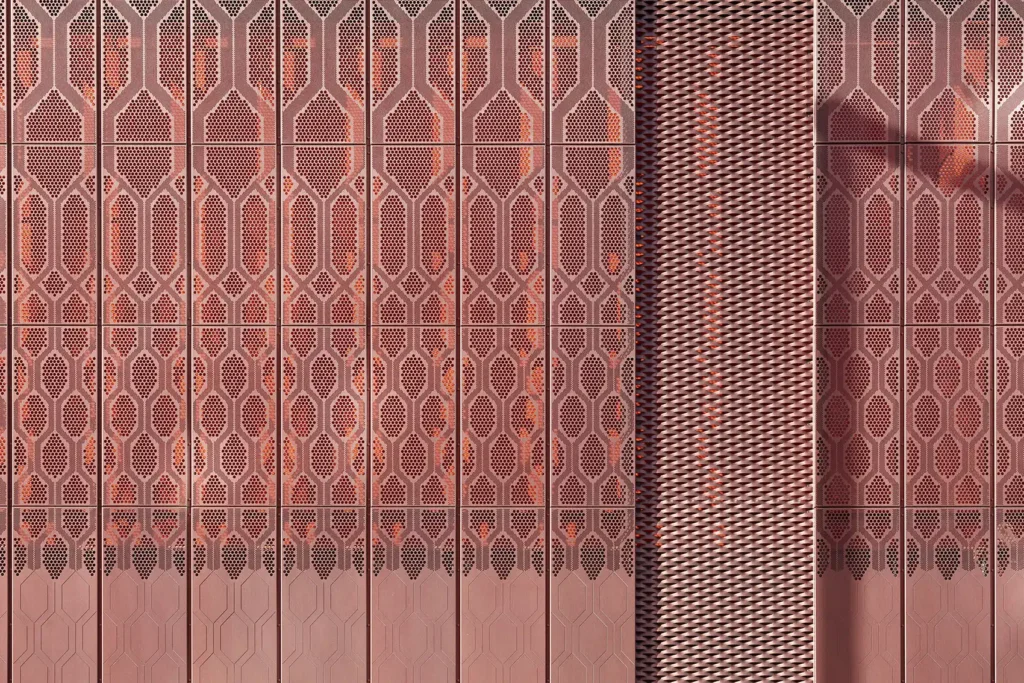

The convergence of technology and architecture has revolutionized the design and fabrication of building facade elements. Computer-aided design (CAD) software and parametric modeling tools allow architects to create intricate and complex facade designs that were once unattainable. Advanced manufacturing techniques, such as computer numerical control (CNC) machining and robotic fabrication, enable the precise fabrication of aluminum panels with customized patterns, textures, and perforations. This level of technological integration not only enhances design possibilities but also streamlines the fabrication process, resulting in cost-effective and high-quality facade solutions.

4. Performance-driven Design:

As buildings become more complex and performance-driven, the role of building facades extends beyond aesthetics to encompass functionality and sustainability. Aluminum panels are engineered to meet stringent performance requirements, including structural integrity, thermal insulation, acoustic attenuation, and fire resistance. Through innovative design strategies and material advancements, aluminum panels can effectively address these performance criteria while maintaining design flexibility and architectural expression.

5. Integration of Smart Technologies:

The advent of smart technologies has permeated various aspects of building design and operation, including facade systems. Aluminum panels are increasingly being integrated with smart technologies, such as sensors, actuators, and automation systems, to enhance building performance and occupant comfort. Smart facade solutions enable real-time monitoring of environmental conditions, adaptive shading control, and energy optimization, thereby optimizing the building’s overall efficiency and reducing operational costs.

In conclusion, the development trend of building facade aluminum panels is characterized by advancements in material science, sustainability practices, technological integration, performance-driven design, and the integration of smart technologies. As architects, engineers, and manufacturers continue to innovate and collaborate, aluminum panels will remain at the forefront of facade solutions, offering a harmonious balance of functionality, aesthetics, and sustainability in the built environment.