In the realm of modern architecture, facade aluminum curtain walls have emerged as a defining feature of skyscrapers and commercial structures, providing a lightweight, non-structural exterior that enhances aesthetics and functionality. Understanding the construction technology behind facade aluminum curtain walls empowers architects, engineers, and building owners to create durable, energy-efficient, and visually striking facades.

Delving into the Structural Components of Facade Aluminum Curtain Walls

- Mullions: Mullions are the vertical members that form the primary structural framework of a curtain wall system. They are typically made of extruded aluminum and are designed to withstand wind loads, dead loads, and live loads. Mullions can be further classified into various types based on their configuration, such as capped mullions, open mullions, and structural mullions.

- Transoms: Transoms are the horizontal members that connect mullions and span across the width of the curtain wall. They provide additional structural support and contribute to the overall rigidity of the system. Transoms can be either pressure plates or mullions that are laid horizontally.

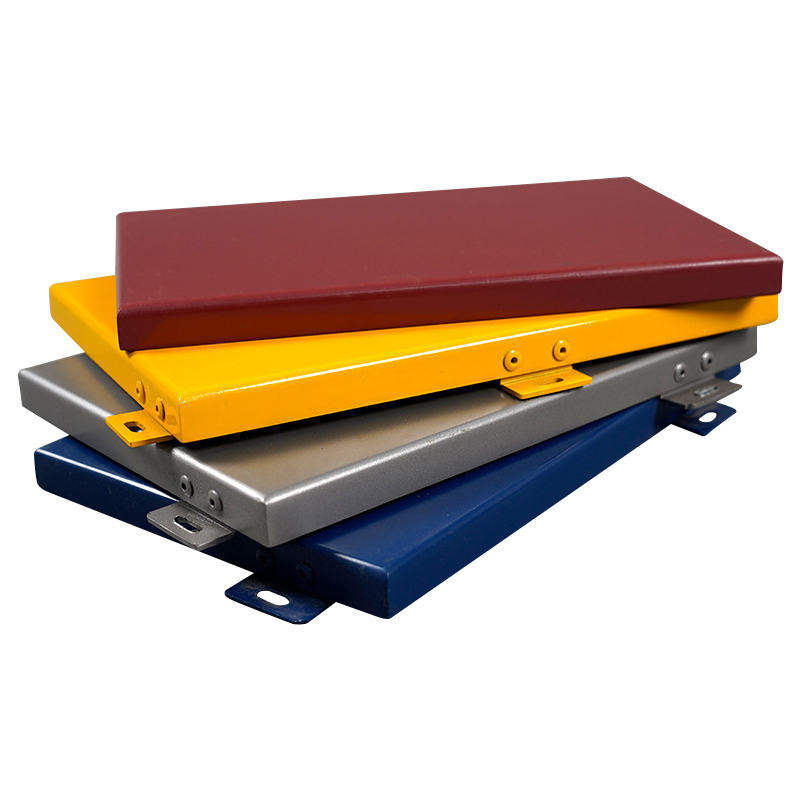

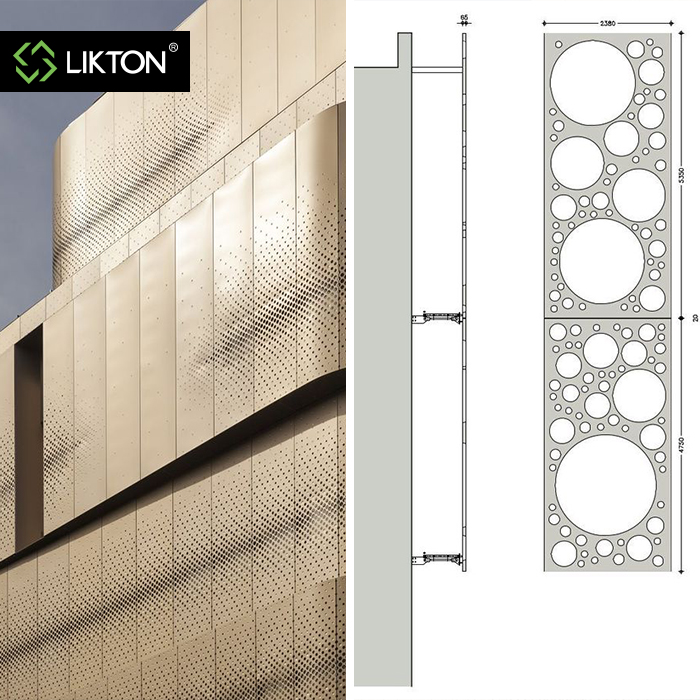

- Cladding Panels: Cladding panels, also known as infill panels, are the non-structural components that fill the spaces between mullions and transoms. They can be made from a variety of materials, including aluminum, glass, stone, and composite panels. Cladding panels provide the exterior aesthetic of the curtain wall and contribute to the building’s thermal and acoustic performance.

- Gaskets and Sealants: Gaskets and sealants play a crucial role in ensuring the watertightness and air-tightness of the curtain wall system. They are typically made of rubber or silicone and are installed between mullions, transoms, and cladding panels. Proper gasket and sealant application prevents water infiltration, air leakage, and drafts, contributing to the building’s energy efficiency and occupant comfort.

- Anchorage System: The anchorage system connects the curtain wall to the building’s structural frame. It typically consists of anchors, brackets, and support plates that are designed to transfer loads from the curtain wall to the primary structural elements of the building. The anchorage system ensures the stability and integrity of the curtain wall under various loading conditions.

Exploring the Construction Methods of Facade Aluminum Curtain Walls

- Stick System: The stick system is a traditional method of constructing curtain walls, where the mullions, transoms, and cladding panels are assembled on-site. This method offers flexibility in design and customization but can be more time-consuming and labor-intensive compared to other methods.

- Unitized System: The unitized system involves prefabricating curtain wall panels in a controlled factory setting. These panels, which typically consist of mullions, transoms, cladding panels, and insulation, are then transported to the construction site and installed as complete units. The unitized system offers faster installation times, improved quality control, and reduced on-site labor costs.

- Semitized System: The semitized system combines elements of both the stick and unitized systems. In this method, certain components, such as mullions and transoms, are prefabricated in a factory, while other components, such as cladding panels, are assembled on-site. The semitized system offers a balance between the advantages of both construction methods.

Benefits of Facade Aluminum Curtain Wall Construction

- Lightweight Construction: Aluminum curtain walls are significantly lighter than traditional masonry or concrete facades, reducing the overall weight of the building. This lightweight construction can lead to cost savings in foundation and framing, as well as improved structural performance in earthquake-prone regions.

- Design Flexibility: Aluminum curtain walls offer a wide range of design options, allowing architects to create visually striking and unique facades. The versatility of aluminum panels enables the incorporation of various materials, textures, and colors, aligning with diverse architectural styles.

- Energy Efficiency: Curtain walls can be designed to incorporate insulation materials and high-performance glazing, improving the building’s thermal performance. This can lead to reduced energy consumption, lower heating and cooling costs, and a smaller environmental footprint.

- Watertightness and Air-tightness: Proper installation of gaskets and sealants ensures that curtain walls are watertight and air-tight, preventing water infiltration, air leakage, and drafts. This contributes to the building’s energy efficiency, occupant comfort, and durability.

- Ease of Installation and Maintenance: Curtain walls can be installed relatively quickly and efficiently, particularly with the unitized system. Their smooth surfaces and lack of joints make them easy to clean and maintain, reducing long-term maintenance costs.

Conclusion

Facade aluminum curtain wall construction technology has revolutionized the way modern buildings are designed and constructed. Its lightweight nature, design flexibility, energy efficiency, watertightness, and ease of installation make it a compelling choice for a wide range of structures. As the demand for sustainable, durable, and