Aluminum curtain walls have revolutionized modern architecture, adorning buildings worldwide with their sleek aesthetics, exceptional performance, and versatility. These non-load-bearing exterior walls, typically composed of aluminum frames and infill panels, offer a myriad of benefits, including enhanced energy efficiency, natural lighting optimization, and architectural flexibility.

Understanding the Anatomy of an Aluminum Curtain Walls

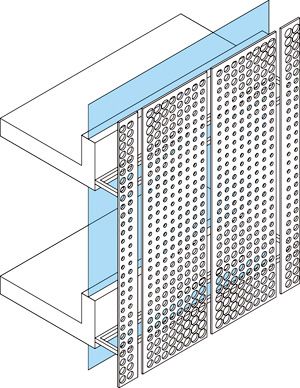

To fully grasp the assembly process of aluminum curtain walls, it’s essential to first understand their constituent components:

- Mullions: The vertical backbone of the curtain wall system, mullions are extruded aluminum members that provide structural support and define the overall grid of the façade.

- Transoms: Horizontal members that connect mullions at predetermined intervals, transoms contribute to the structural integrity of the curtain wall system and provide attachment points for infill panels.

- Infill Panels: The non-structural components that fill the spaces between mullions and transoms, infill panels can be composed of various materials, including glass, metal panels, or stone. They serve as the primary visual element of the curtain wall and contribute to the overall thermal performance and aesthetic appeal of the building.

- Gaskets and Sealants: To ensure watertightness and air infiltration resistance, gaskets and sealants are employed at the joints between mullions, transoms, and infill panels. These components play a crucial role in preventing moisture intrusion and maintaining the building’s envelope integrity.

- Anchors and Brackets: The connection points between the curtain wall system and the primary building structure are established through anchors and brackets. These components ensure the secure attachment of the curtain wall and transfer loads effectively.

- Insulation: To enhance the thermal performance of the curtain wall system, insulation materials are often incorporated within the mullions, transoms, and around infill panels. This helps regulate the interior temperature of the building and reduces energy consumption.

- Accessories: A range of additional components, such as pressure plates, rain screens, and weep holes, may be integrated into the curtain wall system to address specific design requirements and enhance its performance.

Delving into the Assembly Process

The assembly process of aluminum curtain walls can be broadly divided into three main stages:

1. Pre-Fabrication:

- Component Preparation: Individual components, including mullions, transoms, infill panels, gaskets, sealants, and accessories, are meticulously manufactured and quality-checked to ensure precise dimensions and adherence to specifications.

- Frame Assembly: Mullions and transoms are assembled into frames, ensuring proper alignment and structural integrity. Gaskets and sealants are applied to joints to create a watertight seal.

- Infill Panel Installation: Infill panels, such as glass or metal panels, are carefully inserted into the frames, ensuring proper fit and secure attachment.

2. On-Site Installation:

- Preparation and Layout: The building façade is prepared for curtain wall installation, ensuring a level and stable surface. Layout marks are established to guide the precise placement of curtain wall units.

- Unit Handling and Lifting: Curtain wall units, pre-assembled at the factory, are carefully transported to the installation site using cranes or hoists.

- Unit Placement and Alignment: Curtain wall units are precisely positioned according to the layout marks, ensuring proper alignment and verticality.

- Connection and Sealing: Units are securely connected to the building structure using anchors and brackets. Joints are sealed with gaskets and sealants to maintain watertightness.

3. Final Inspection and Adjustments:

- Visual Inspection: The entire curtain wall system is thoroughly inspected for any visible defects, ensuring proper alignment, joint integrity, and overall aesthetic appeal.

- Functional Checks: Watertightness tests are conducted to verify the effectiveness of gaskets and sealants. Drainage systems are checked for proper functionality.

- Adjustments and Refinements: Any minor discrepancies or imperfections are identified and addressed through adjustments and refinements to ensure the curtain wall system meets all performance and aesthetic requirements.

Conclusion

The assembly of aluminum curtain walls involves a meticulous process that encompasses pre-fabrication, on-site installation, and final inspection. Each stage plays a critical role in ensuring the structural integrity, watertightness, aesthetic appeal, and long-lasting performance of the curtain wall system. By employing skilled technicians, adhering to strict quality control measures, and utilizing advanced installation techniques, architects, engineers, and construction professionals can create stunning and sustainable curtain wall facades that enhance the value and visual impact of modern buildings.